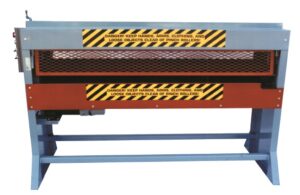

Mar-Bel Pinch Rollers

MAR-BEL ASSOCIATES and its predecessors have manufactured machinery for the laminate industry since 1958. The equipment has a well deserved reputation for reliability and customer support. For these reasons it is found in the quality control, research, or operations departments of such industry giants as FORMICA® Corporation, Ralph Wilson Plastics’ WILSONART® division, International Paper’s NEVAMAR® division and WESTVACO®. It is as easily found in two employee shops because of its versatility and value pricing.

Because of the open end, the PRO-7 has the capability of handling “L” shapes and oversize flat widths. The ability to handle oversize flat widths makes it more flexible and versatile than closed end pinch rollers of equivalent size since the oversized piece can be turned around and the unpressed end can also be rolled.

BENEFITS

- A 4×8 panel is rolled in 22 seconds instead of the customary 7-8 minutes experienced in hand rolling

- No quality control problems with callbacks due to poor, uneven laminating pressure – a superior, more uniform bond.

- Cost justified with a value price: Often the labor and material savings of one job or the avoidance of one delamination / product rework / warranty call can pay for the machine.

FEATURES

- 1500 lbs. of line pressure is more than adequate for normal laminating operations

- Note that the top roll in each size is 1-1/2″ longer on one end than the bottom roll to accommodate a raised edge: e.g. the 51-1/2″ size has a top roller that is 53″ long. This will allow a standard depth clearance of up to 2″ of build up on that end(see inset photo – front).

- 27 FPM roll speed, standard 3″ opening for material thickness, top of bottom roll is 33 1/4″ from floor (pass height). Adjust

this measurement if you add casters to predrilled machine pads - Standard roll material is 60 durometer neoprene with matte’ finish (other coverings and/or durometers quoted on request).

- Since you set your top roller to a specific opening for a particular laminating operation, you don’t experience fractured laminate on the leading edge when it overhangs the substrate which may sometimes occur while forcing open pneumatically operated rollers. With our opening mechanism you avoid having to compensate for this problem by using less pressure than you want in a pneumatic system or requiring an employee to remember to increase the pressure once the work has been fed. In addition, our crank mechanism remains consistent over its long operating life while one of the cylinders in a pneumatic system may eventually have a different output pressure which would result in uneven surface pressure.

VERSATLITY

- Mar-Bel pinch rollers have been used for putting clear on aerial overlays, foil on styrofoam pontoons, the manufacture of computer flooring, boat manufacturing and a host of other applications in addition to the cabinetmaking and casegood / store fixture industries.

SAFETY

- Electric motor brake for instant stops-Activated by gate movement or Red mushroom emergency stop button

- Safety gates with interrupt circuit that must be reset if the gate switch is activated by the operator(we have latched – not momentary – circuitry). Gates move up and down with top roll as the roll opening is adjusted. Bottom guards in safety red are standard.

OPTIONS

- Segmented rollers-fixed or movable-provide drawing/sketch for a quote

- Custom roll surfaces (e.g. Silicone, Teflon® for slippery surface)

- Custom openings for thicker products and custom widths for wider materials

- Custom electrics and motors